Air Flow Diagnostics & Energy Savings Audits

From production to packaging

Air Flow Management

Managing air flow on factory scale to reach highest level of sanitary safety

APPLICATION

Step 1:

Identifying contamination factors

Humid ambient air – materials to be processed – operating machines – production area – personnel

Having identified all the contamination factors, Air Quality Process determines their additional and interactive combinations as well as the multiple levels of pollution they generate.

Establishing various degrees of identified factors’ exposure and sensitivity to the contamination. The latter determines the classification per zone and the premises in decreasing order of danger level.

APPLICATION

Step 2:

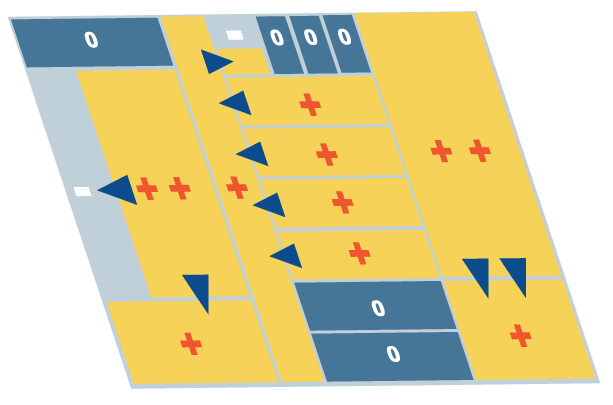

‘Forward flow’ organisation

The main requirement is to avoid cross-contamination from a polluted zone to a pollution-free zone by respecting the direction in which the products circulate. To achieve this goal, Air Quality Process organises air transfer from the most sensitive points to those that are less so by putting in place:

- positive air pressure in the most sensitive rooms,

- decompression in less sensitive rooms,

- extraction of polluted air in the most polluted places (washing plant for example),

- centralised control of all air flow components.

APPLICATION

Step 3:

Development plan recommendations

From the results of investigations and the defining of principles, our design office prepares:

- a specific development plan for global, hygienic management of air flow,

- a structural fit-out of premises: protection airlock, sectional doors, smooth water repellent materials, identification.

APPLICATION

Step 4: Fresh and handled air

We determine and supply the following equipment according to your needs:

- ultra-clean fresh air designed to create positive pressure in premises as well as the renewal of air as needed for products and personnel. We install air handling units in the most sensitive premises so as to perform triple filtration: terminal gravimetric, opacimetric and absolute (HEPA). These units are operated and maintained individually.

- additional equipment: extractors, decompression grills…

- control equipment: sensors, probes, regulations, automatons.