Serving the world cheeses

Servi Doryl designs and manufactures a wide range of cheese moulds & ageing solutions

for every type of cheese

Pressing Moulds

Technology for semi-hard and hard cheese moulds

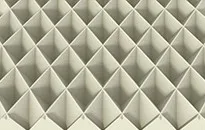

Over 40 different combinations of patterns and perforations

for a mould perfectly suited to your technology

Wide range of combinations

Each cheese and each technology calls for the very best combination between the pattern (print left by the mould on the cheese) – which determines the draining and closing of the rind – and the perforations, which let the whey seep outside of the mould. Servi Doryl offers:

- A choice of depth of pattern, from the finest to the most marked,

- A selection of grained, straight, square or cross print,

- Various micro-perforations, conical or cylindrical, and adjustable perforation density.

APPLICATION

Boilermade moulds or block-moulds

Wheter you need cheese moulds for the production of Gouda, Edammer, Leidse, Kanter, Maasdammer, or even plant based cheese moulds, we adapt our technology and design to your needs.

Single moulds or grouped into multimoulds can be offered in all different combinations of patterns and perforations.

APPLICATION

Gouda mould & lid

Individual moulds or grouped into block-moulds. The moulds can be customised, using one of the many combinations of possible patterns and perforations.

Gouda moulds are available in many different sizes starting from 2kg up to 60 kg.

APPLICATION

Euroblock

The Euroblock moulds can be customised, using one of the many combinations of possible patterns and perforations. Able to withstand high pressure with additional stainless steel belts. Available in various dimensions.

APPLICATION

Block-moulds & block-lids

Moulds grouped into block-moulds. The moulds can be customised, using one of the many combinations of possible patterns and perforations.

Available in many different shapes and sizes.

APPLICATION

''Log'' type mould & lid

Individual moulds or grouped into block-moulds. The moulds can be customised, using one of the many combinations of possible patterns and perforations. Able to withstand high pressure with additional stainless steel belts.

Suitable for all kind of cheese types, like Carron cheese, loaf cheese and many others.

APPLICATION

Moulds and acidification plates

The moulds and acidification plates help to maintain the shape and pattern of your choice during acidification and brining where applicable. Our specific perforations allow the brine to penetrate, through the mould, right into the centre of the cheese.

APPLICATION

Marking plates

Moulds can be equipped with customised marking plates that suits customers’ brand.