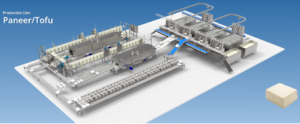

Last summer ALPMA extended the FORMATIC portioning device at cheese dairy Rouveen Kaasspecialiteiten. This innovative system is suitable for the production of cheese with closed cutting pattern or fermentation holes. The FORMATIC has proven to be the optimal solution for Rouveen Kaasspecialiteiten. After 15 years of operation, it was time to increase capacity.

The need to expand a production facility is primarily a reflection of a cheese dairy’s success and ability to secure a significant market share with high-quality and competitively priced products. A few months ago, a major intervention in the plant commissioned by ALPMA in 2007 to increase the production volume was on the programme. Due to the technical complexity and the tight time frame for the implementation, precise preparation was required from both ALPMA and Rouveen Kaasspecialiteiten right from the start. The tight space conditions on site posed additional challenges.

Such a demanding project can only succeed with intensive teamwork between the customer and supplier in all phases of the project. Professional project management on both sides and exemplary co-operation between the installation and commissioning teams on site were the key to the success of the project. The plant finally went into operation on time. The promised performance values have now even been significantly exceeded.

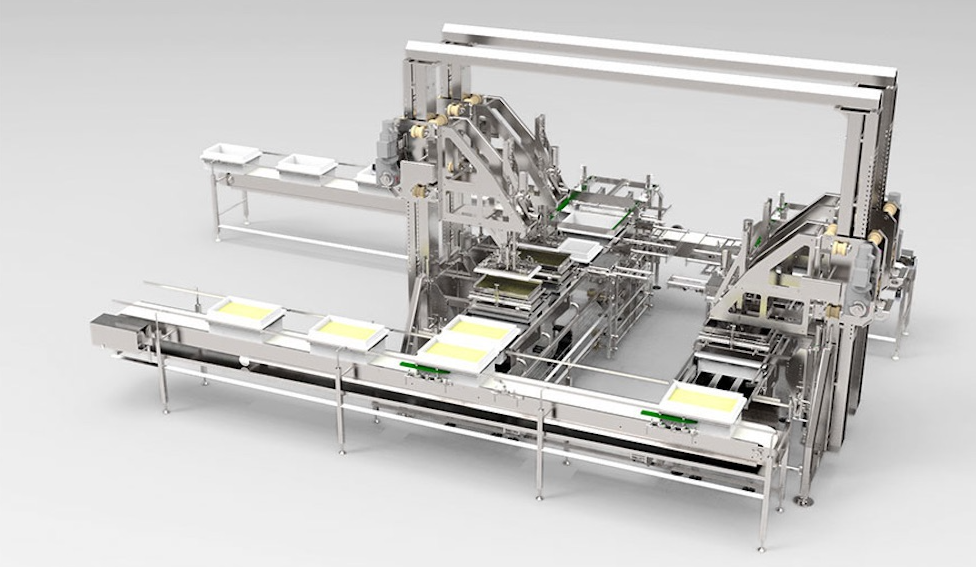

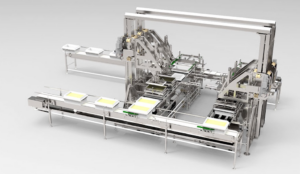

The FORMATIC is one of the automatic filler units to meet the high requirements for curd filling in the semi-hard and hardcheese manufacturing process. The system includes filling and pre-pressing of the curd directly in the mould avoiding air entry in the curd (fermentation holes), as the curd remains below whey level. The system is known for its small footprint, weight accuracy, flexibility in speed and applicable for a wide range of cheese shapes, from bread to big-block, with short change over times between different formats.

Learn more about the FORMATIC and other portioning devices