Full range supplier for cheese makers worldwide

As an experienced full-service provider, ALPMA supports clients from idea to final project

ALPMA

Complete solutions for the entire dairy industry

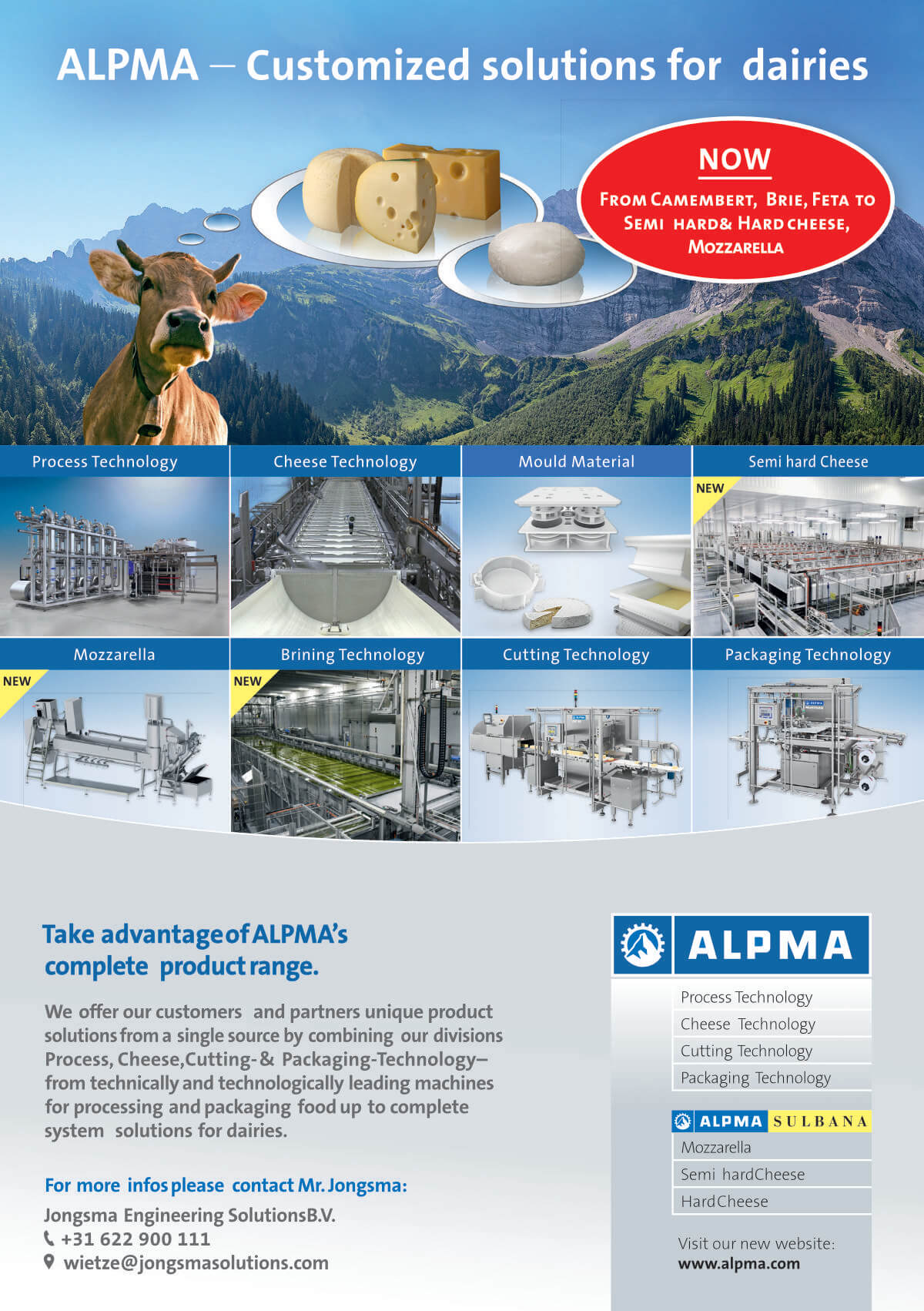

ALPMA is the world’s leading milk and whey processing, cheese technology and cutting and packaging technology company.

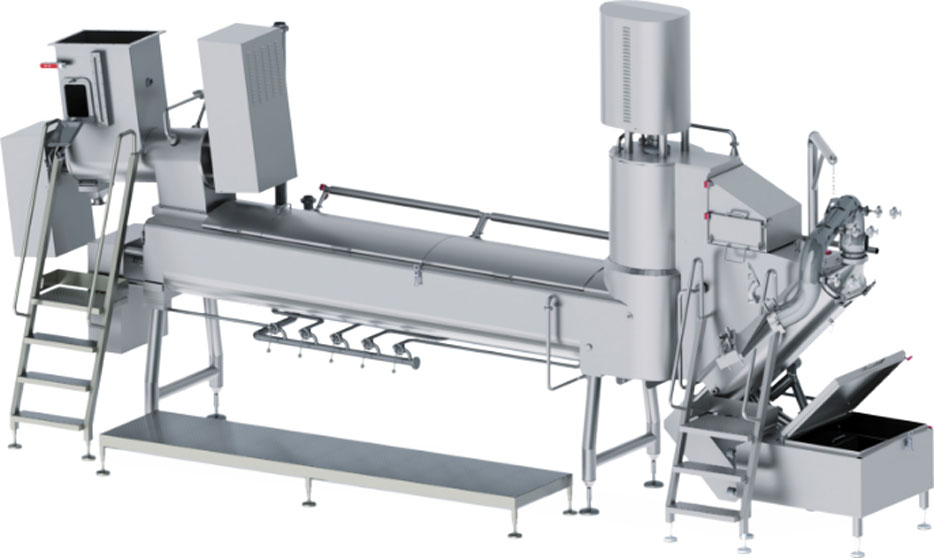

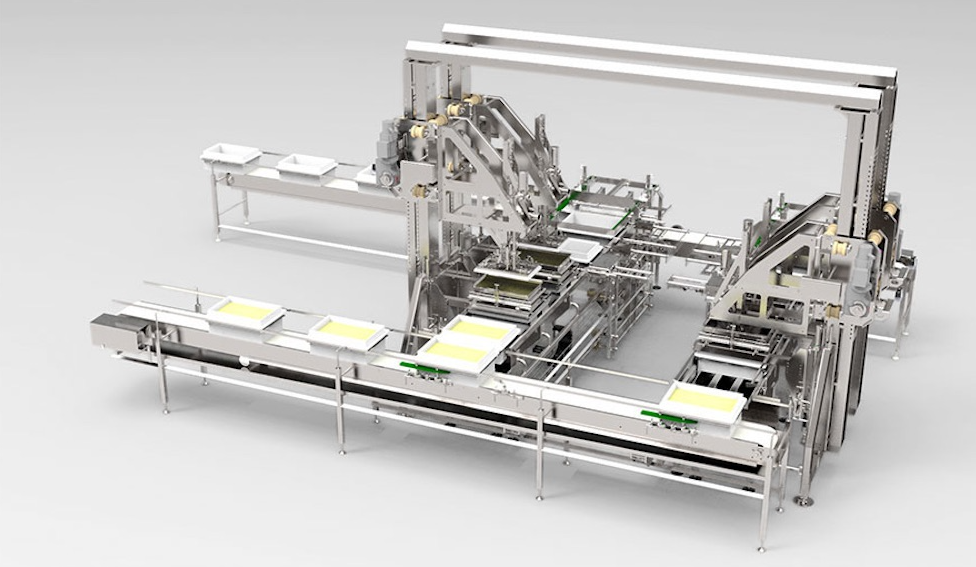

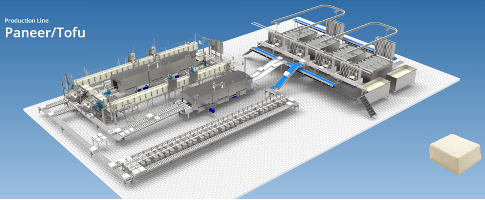

In addition to process technology expertise, ALPMA has the technological competence for cheese production of any type of cheese (twarog, soft cheese, semi-hard cheese, hard cheese, pasta filata and tofu). ALPMA is an expert in complete cheese production lines, from curd preparation to filling systems, cheese vats, cheese pressing systems, brine baths and the complete mechanization of the lines.

ALPMA is known for innovation and customized solutions. Thus, ALPMA supplies the Formatic and Coagulator that enable the most efficient cheese production. The latter innovation is a fully automated continuous curd preparation that ensures the highest possible yield. One hundred Coagulators are now in operation worldwide.

Together with its subsidiary LTH Dresden, ALPMA has been supplying innovative installations for the food industry around the world for more than 20 years. ALPMA specializes in pre-processing milk for dairies and further processing sweet and sour whey into high-quality whey protein products.

For more information about our expertise in plant engineering and all applications in membrane filtration, please refer to ALPMA’s home page.

May we introduce – VeganoProt® – our new line for Vegan Protein Diversity.

Plant-based foods are on the rise, and this trend is being reflected in the increased popularity of vegan cheese, yogurt, and milk alternatives. A study by Mintel found that consumers are becoming more and more open to alternative products, resulting in a surge in innovation in plant-based foods.

For example, in the past three years, the number of new vegan cheeses launched globally has increased by an average of 17 percent year-on-year. This growth is being driven by countries like Germany, the United States, and Canada, where the largest dairies have entered the market to launch plant-based variants under their well-known brands.

We at ALPMA have been working with vegetable protein, such as those from peas and plant starch, for a long time. Now we are bringing these activities together under the trademark VeganoProt®. The new line supports a diversity of vegan protein – whether from starch or oil plants or protein obtained by fermentation.

So, regardless of what type of protein, ALPMA supplies customized equipment for producing plant-based products. ALPMA’s proven process technology and the resulting improved taste of these plant-based products make them more attractive and convenient for consumers.

ALPMA offers the customer security in case of calamities to the membrane plant. Free storage of customer- and application-specific membranes at ALPMA saves customers time, storage costs and energy while increasing plant production reliability.

How does the membrane service work? ALPMA develops a carefully tailored quotation for the desired membrane modules. After placing the order, the membranes will be stored at ALPMA under proper conditions in Dresden, and ensures that they are available to the customer at all times within 3 business days. This allows sudden production problems to be met at very short notice.

ALPMA designs and manufactures systems for a wide range of cheese types and farm sizes. An ALPMA line is designed to be modular and can therefore be adapted incrementally to the growing size of the company.

The variety of semi-hard cheeses is enormous. Therefore, each product requires an individual production line. For this reason, ALPMA joins its expertise with SULBANA to present to you a comprehensive range of solutions and techniques.

An innovation engine in pasta filata and mozzarella, Sulbana has earned an excellent reputation. To maximize synergies, SULBANA’s cheese-making technology division is now under the roof of the ALPMA Group. This enables ALPMA to offer customers a customized and comprehensive service in the field of cheese preparation technology.

An innovation engine in pasta filata and mozzarella, Sulbana has earned an excellent reputation. To maximize synergies, SULBANA’s cheese-making technology division is now under the roof of the ALPMA Group. This enables ALPMA to offer customers a customized and comprehensive service in the field of cheese preparation technology.

Full range supplier for cheese dairies

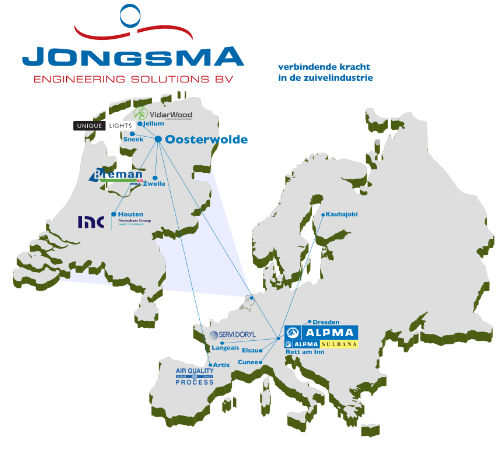

ALPMA’s headquarters are located in Rott am Inn/Bavaria (Germany). With its subsidiaries and agencies and more than 900 employees worldwide, we care for and work with our customers to ensure ALPMA’s success. Driven and supported by two CEOs with experience, strong leadership and an international, overarching business strategy. This allows ALPMA to respond with expertise and flexibility to regional and local issues where we can switch in the client’s native language.

Business association with additional benefits

Our company’s cooperation with the Alpenhain dairy and the specialized packaging company FRISCHPACK offers our customers a unique additional advantage: the rare opportunity to see many ALPMA machines in operation in the immediate vicinity.

Through close communication with users of our machines within this association, we receive not only qualified technological feedback, but also wishes and suggestions regarding our installations. Our customers benefit from this valuable information – with it, the latest forms of ALPMA technology have been tried and tested within this association.

Brochure

Customized solutions for dairies

Want to know more about our partner ALPMA’s solutions? Then read the attached brochure. If you are interested in this solution for your business, please contact us using the form at the bottom of this page.

Update

Latest Alpma News

ALPMA Support & Optimization After-Sales Process Technology

ALPMA is expanding their service department with comprehensive on-site and online support and customized service & maintenance. Find out how ALPMA’s After-Sales Process Technology can

New Flyer Precision Fermentation – from Concept to Realization

ALPMA’s process technology division combines years of experience in the extraction and processing of proteins from various sources. These include from precision fermentation, an innovative

Anuga FoodTec 2024 – coming soon!

In less then two months the ANUGA FoodtTec 2024 will take place in Cologne. From Tuesday 19 to Friday 22 March to be exact. Under

Succesfull capacity increase at Rouveen Kaasspecialiteiten

Last summer ALPMA extended the FORMATIC portioning device at cheese dairy Rouveen Kaasspecialiteiten. This innovative system is suitable for the production of cheese with closed

Tofu (plant-based cheese alternative) and Paneer experience remarkable boom

With the right equipment, cheese makers are able to tap into the growing market of Tofu and Paneer cheese. Especially Tofu has experienced a remarkable

ALPMA News & Trends – Process technology for plant based foods

The latest edition of ALPMA News & Trends highlights current topics and projects, including the developments of VeganoProt, ALPMA’s line for Vegan Protein Diversity, which was launched last year.