With the right equipment, cheese makers are able to tap into the growing market of Tofu and Paneer cheese. Especially Tofu has experienced a remarkable boom in recent years and has become a popular choice for consumers who prefer plant based foods.

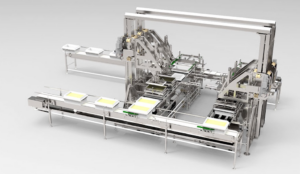

Precision and efficiency are key factors in tofu production. This is where the specially developed tofu filling plant comes in. The plant is equipped with state-of-the-art cutting technology, which ensures that the tofu is cut into equal portions. This ensures consistent product quality and stability, which is essential for the production of high-quality tofu. Another great advantage of our solution is the flexibility in using different format sets, allowing different shapes and sizes to suit market requirements. After portioning, the tofu portions are placed on a conveyor belt and go directly to a packaging machine.

Continuous curd preparation in Basin system

In addition to single filling plants, ALPMA has a fully automated production line specifically designed for Tofu and Paneer, in order to achieve the highest possible quality and efficiency. The main component of this line is the fully CIP cleanable Basin system, which allows a production time of up to 20 hours per day. A major advantage of the Basin line is the preparation of the curd in small basins (curd bins). This method ensures constant moisture content of the product and ultimately provides the highest yields. The Bassin line is the basis for optimal production of soft cheeses, such as feta, mozzarella, blue cheese, and thus also for tofu and paneer.