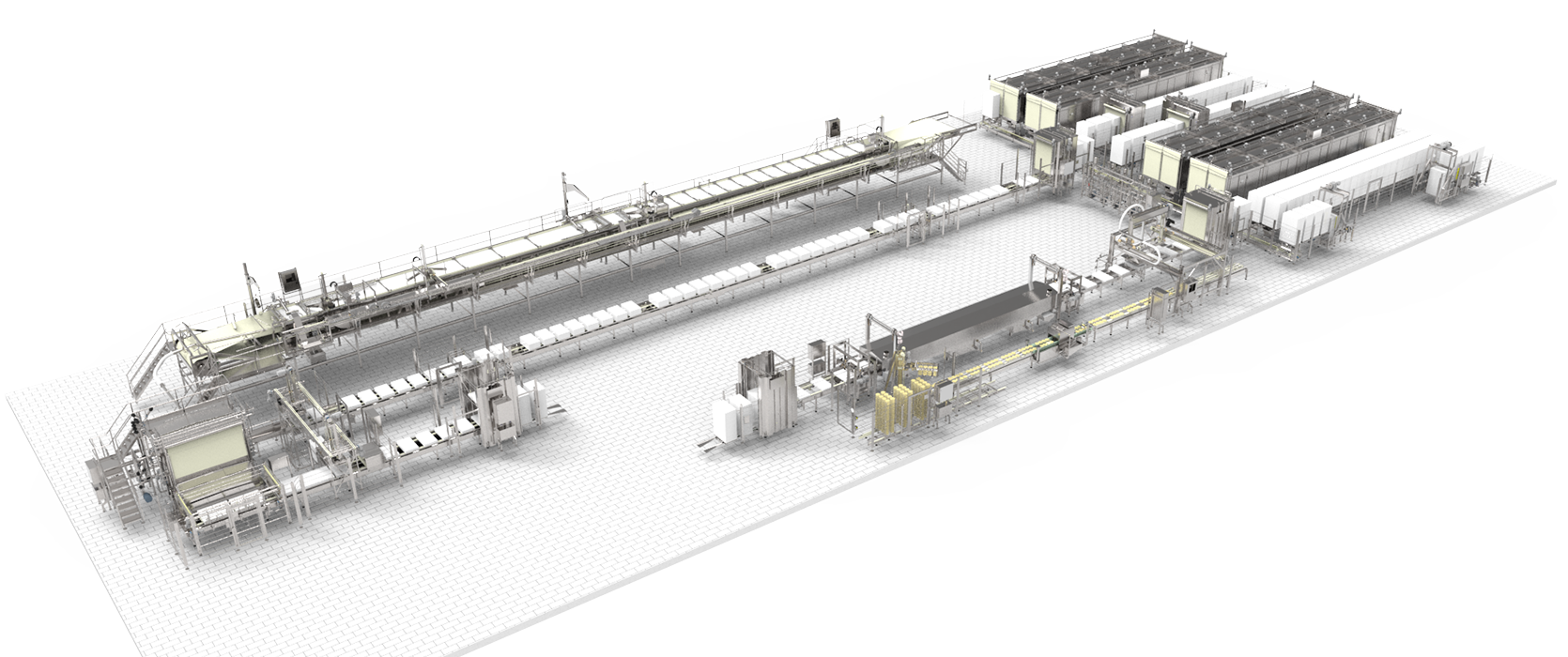

Cheese Production Technology

Technological competence and equipment for every cheese type and dairy size.

Soft Cheese

Production Line

APPLICATION

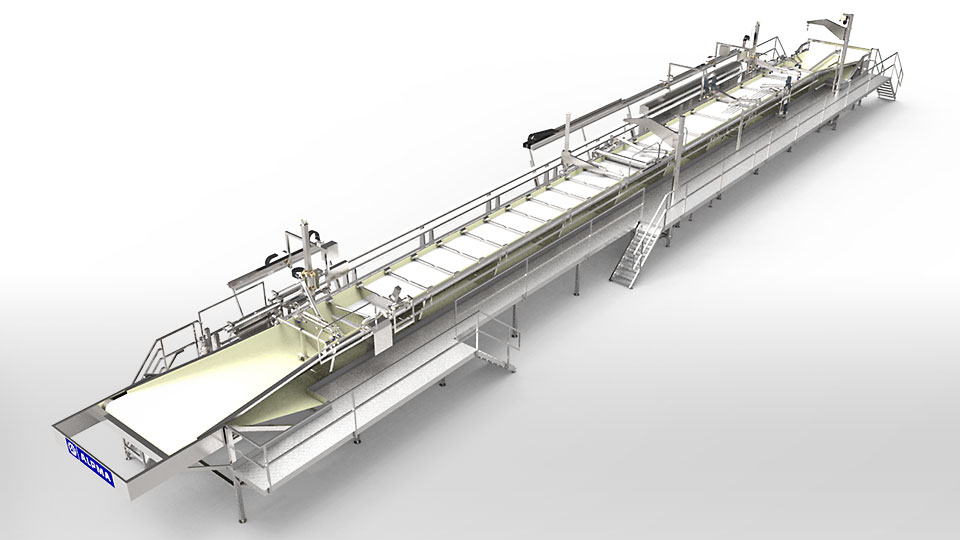

Coagulator

Continuous curd preparation for highest possible yield. Capacities from 5,000 l/h to 45,000 l/h. Variable coagulation time. Fully automated unit. Uniform cutting of the curd. Flexibility in curd treatment. Lowest possible losses in fines. Lowest standard deviation of moisture.

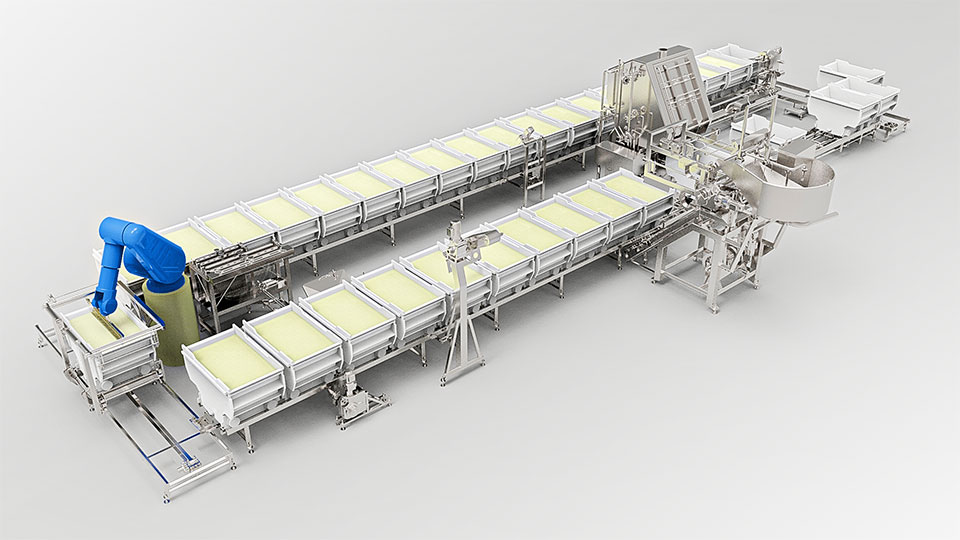

APPLICATION

Bassine-System

Curd preparation in a batch process with various levels of automation. With plant capacities up to 30.000 l/h. Individually designed systems offer the greatest possible flexibility, suitable for many types of cheese.

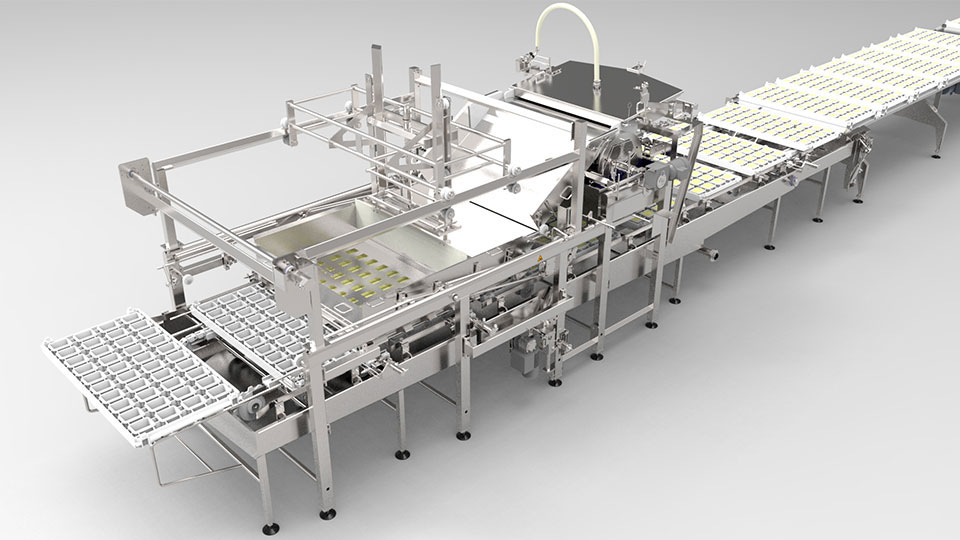

APPLICATION

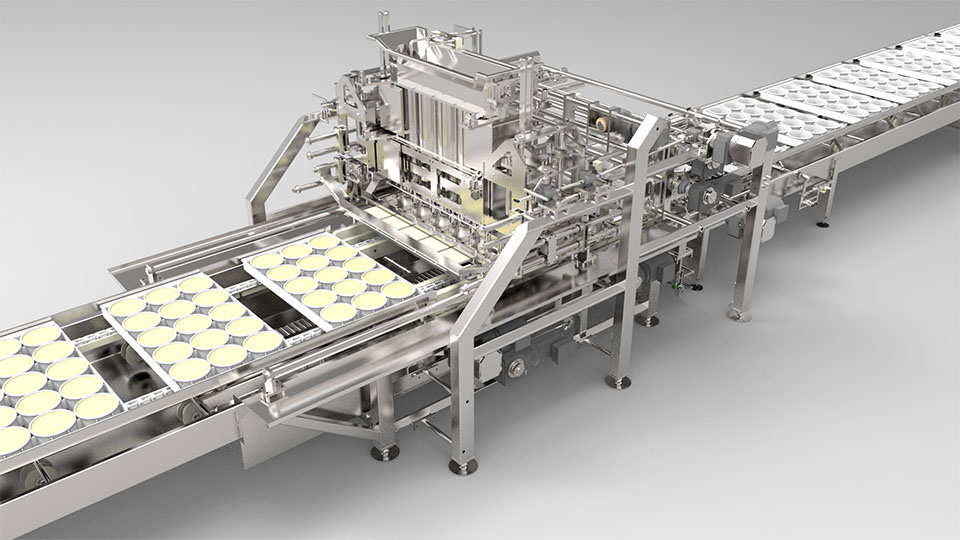

Filling device AFE

Filling device with integrated pre-draing for semi or fully automatic distribution of curd into blockforms with flexible formats. Easy change of formats with filling plate.

APPLICATION

Portioning ARP/ABP

Fully automatic portioning unit with integrated pre-draining for compact and exact weight dosing of soft cheese curd in block forms. Pre-pressing by gravity in the column. Different format sets ensure high flexibility.

APPLICATION

Portioning MR

Fully automatic highspeed trommel rotation filler with integrated pre-drainage for exact weight potioning for soft cheese curd.

APPLICATION

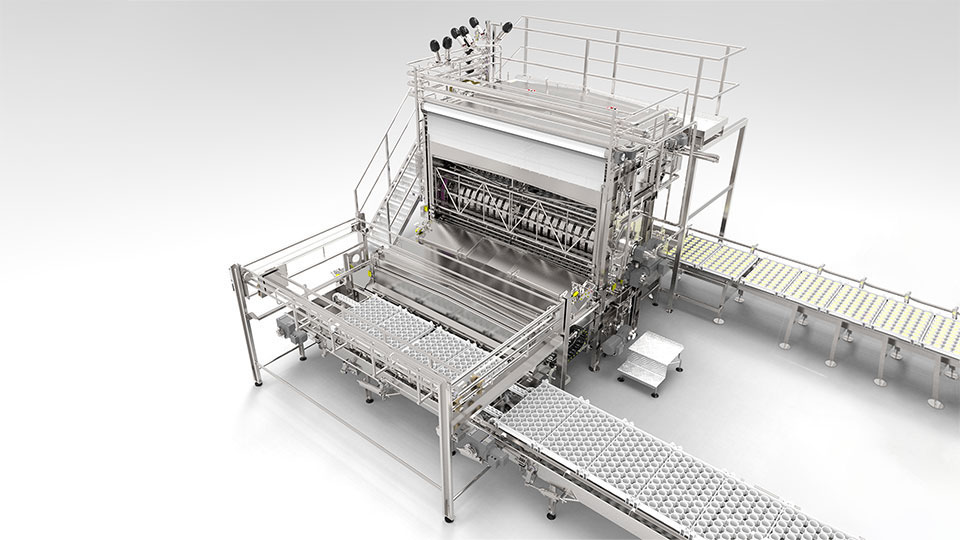

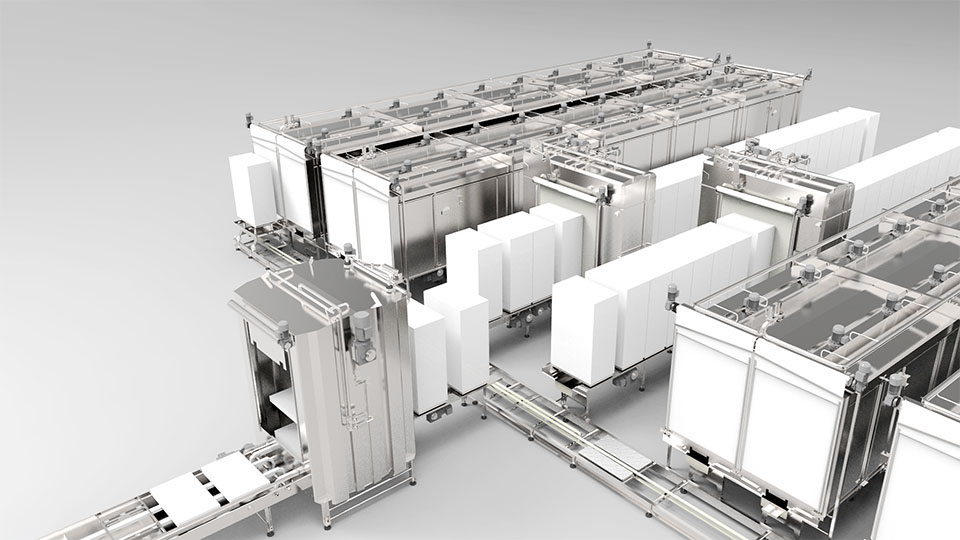

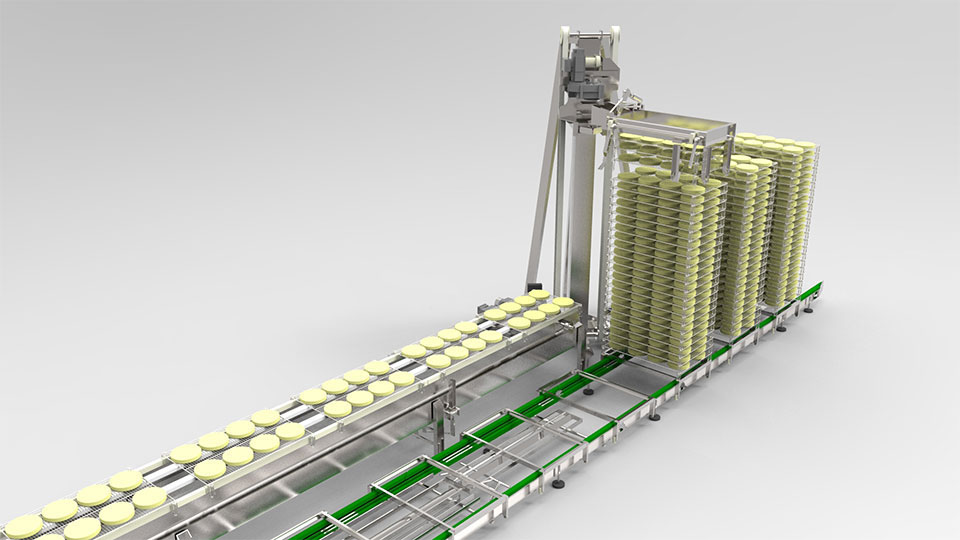

Automation Systems

Fully automated mechanization line for blockform stacking, transport, climatisation, transfer and stack turning and destacking of production material during draining and acidification.

APPLICATION

De-moulding systems

Semi- or fully-automated line for removing the cheese from the block forms using a vacuum.

APPLICATION

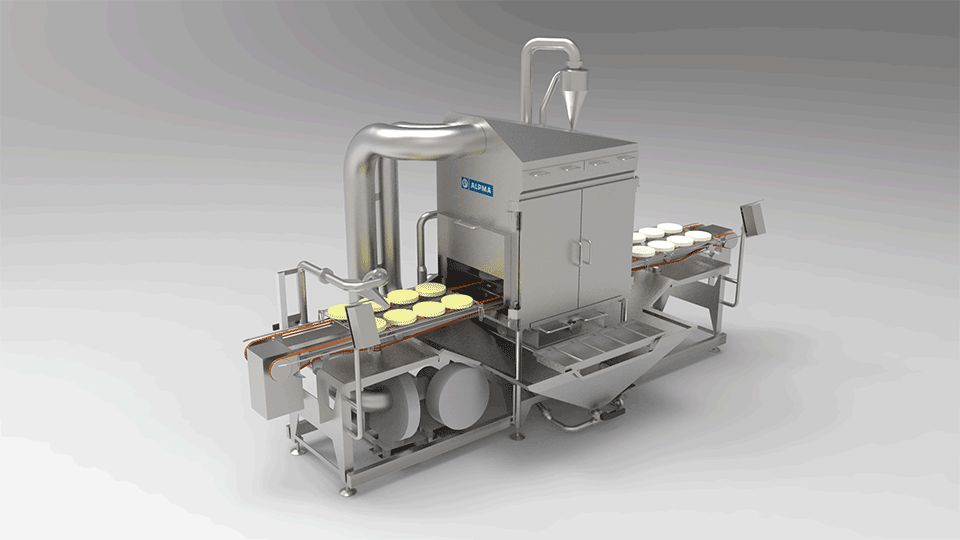

Dry salting machine

Continuous dry salting of cheese on one or both sides.

APPLICATION

Brining systems

Brining systems for salting in blockform or tray stacks as well as rack systems with manual or fully automatic loading and unloading.

APPLICATION

Stacking and destacking systems

Units for stacking, destacking and moving production material (i.e. cheese moulds).

APPLICATION

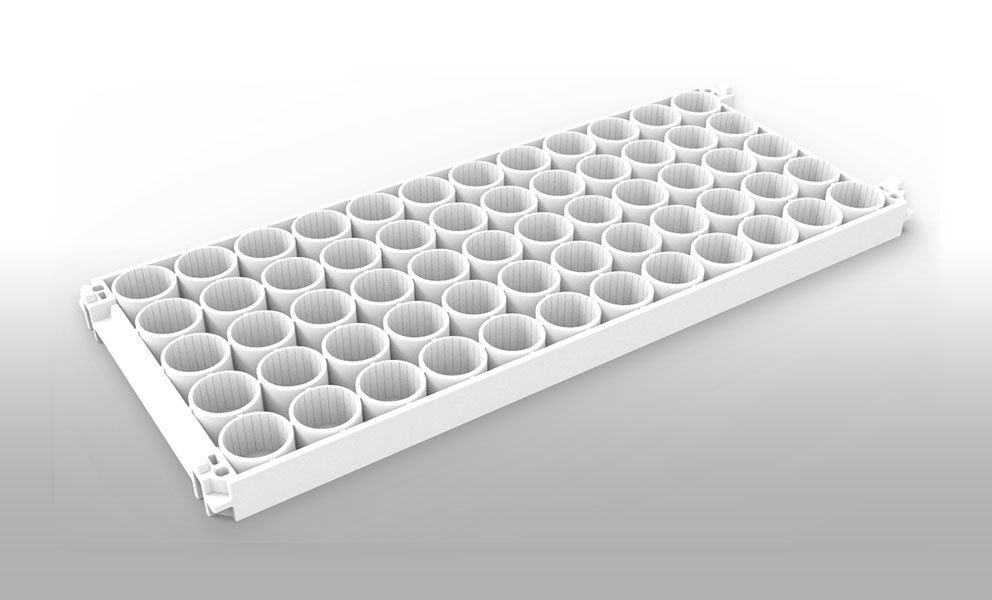

Cheese moulds

Blockforms: designed for optimal whey removal, acidification and climate control during the draining phase.

See the range of cheese moulds on main products page.

APPLICATION

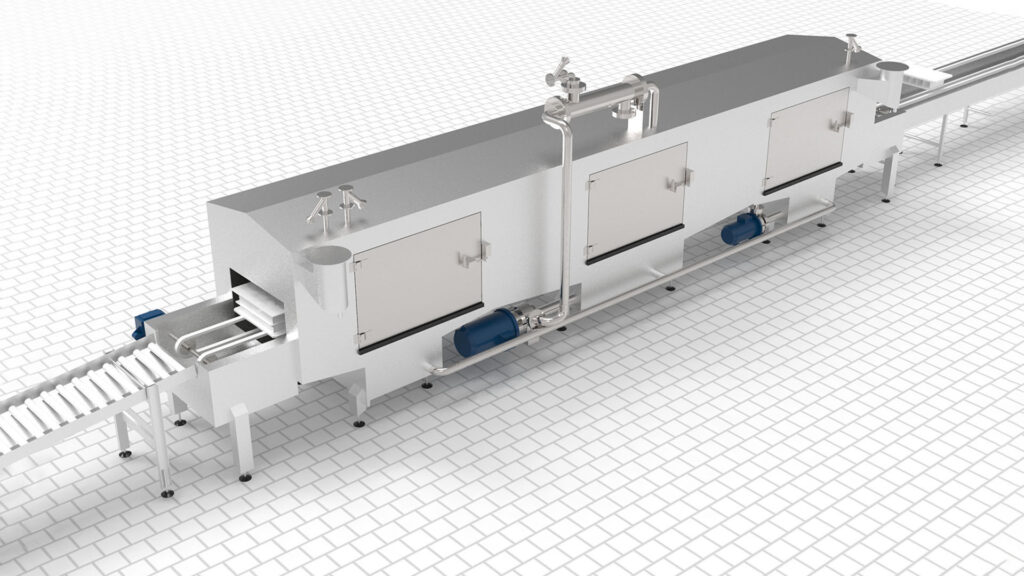

Mould cleaning tunnel

Continuous cleaning of the cheeseforms (single-phase or multi-phase).