Serving the world cheeses

Servi Doryl designs and manufactures a wide range of cheese moulds & ageing solutions

for every type of cheese

Soft Cheese Moulds

A wide range of solutions adapted to your production process

APPLICATION

Coagulation vats (Bassines)

Used for complete coagulation process with optimal hygienic design, making it ideal for small sized dairy producers.

Wide range of coagulation vats adapted to automated or manual slicing and mixing tools, with or without wheels. We can advise you on choosing the shape that is most suited to your manufacturing (semi-spherical, semi-elliptical, semi-cylindrical, or flat-based), with capacities that can reach up to 675 litres.

APPLICATION

Complete moulding set

Servi Doryl offers two types of moulding and draining systems for soft cheese:

- the open system, where bottomless moulds are placed on draining mats which are in turn placed on draining trays.

- the bottom system where moulds with bottom are used for moulding and draining in block-on-block stacking.

APPLICATION

Curd distributor - stainless steel, alluminium or plastic

Enable regular distribution of the curd among block-moulds and block extensions, with precision to guarantee a perfect weight distribution of the cheese. Perfectly suitable for our coagulation vats, which allows for the cutting of a precise volume of curd and for the transferring of it into block-moulds, without loss of material. Adaptable to any product shape.

APPLICATION

Moulds & block-moulds (bottom)

The bottom system and the perforation ensure both safe moulding and draining with the possibility of stacking mould on mould. The moulds can be used individually or assembled into block-moulds.

APPLICATION

Block-moulds (special shapes)

The moulding solutions are suitable for all types of users. Quick demoulding by simply turning. Easy handling. Optimal curd distribution and cheese yields.

APPLICATION

Moulds & block-moulds (extensions)

The bottom system and the perforation ensure both safe moulding and draining with the possibility of stacking mould on mould. The moulds can be used individually or assembled into block-moulds.

APPLICATION

Goat cheese moulds

The moulding solutions are suitable for all types of users.

Block-moulds or individual moulds with their dedicated supports allow fast and secure processing of your products.

APPLICATION

Draining trays - stainless steel or aluminium

Developed to mechanise and secure the turning of cheese in stack, the double-sided plastic draining trays can replace stainless steel and aluminium trays. They work for all cheese shapes and can be adapted to mechanised lines.

APPLICATION

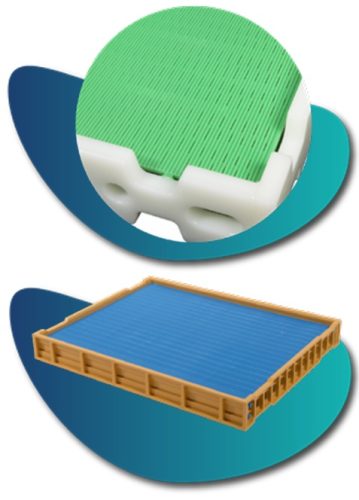

Double sided draining trays (patented anti-drop system)

Two patented models that can be used for all soft cheeses:

- The multiformat double sided plastic tray with sloping gutters has the ability of channelling air and whey. Fitted with draining mats, it allows for optimum ventilation and draining of cheese.

- The drip prevention system stops the product whey from dripping down on to the cheese stacked below.

APPLICATION

Draining & ripening mats

Servi Doryl draining mats are placed or are attached on draining trays, in order to remove the whey. According to the nature of the cheese, various options are available. Our mats are manufactured to your specifications, and can optionally be detected by an X-ray or metal detector. Our colour range will provide you with easy identification on the production line.

APPLICATION

Stack turner

Stack turners assists in the draining and formation of the cheese. The hygienic design allows easy and safe handling by cheese makers.